Turn any spare wall into a guest room—no contractor required.

1️⃣ Introduction to DIY Murphy Beds

Why do you want to know How to Make a Murphy Bed from Scratch? Here’s why,

You need an office and a guest room, but you only have one wall. The Murphy bed Your full-size mattress that effortlessly folds away into a sleek cabinet, instantly reclaiming your space for 364 days a year. Buying a pre-built unit can run $1,500–$3,000; building your own costs $300–$600 and takes a single weekend once you know the steps.

At the end of the article, we have another article where we discuss which mattress is best for a Murphy bed. Keep Reading. ENJOY 🙂

2️⃣ Murphy Bed Design Options

📐 Vertical vs. Horizontal Murphy Beds – Which Is Easier to Build?

| Vertical (up & down) | Horizontal (side flip) |

| • Most common plans online | • Great for low ceilings (5 ft) |

Beginner pick: Vertical—plans and hardware kits are everywhere, and the math is simpler.

🗄️ Cabinet vs. Simple Wall-Mounted – Differences in Complexity

- Cabinet Style

– Looks like built-in furniture

– Adds $150–$300 for plywood and trim

– Requires basic cabinet-making skills (pocket holes, edge banding) - Wall-Mounted Frame Only

– Mattress sits in a bare metal/wood frame that flips up

– Faster build (one afternoon)

– Exposed hardware—fine for garages, studios, or minimalist vibes

🛠️ Fold-Down Desk or Shelving – Multi-Functional Designs

- Desk front: The face panel drops to become a desk; bed folds over it.

- Bedside Library Walls: Floor-to-ceiling bookshelves hug the bed’s sides, disguising the frame and doubling as a functional book haven.”

- Pro tip: Build the desk first; the bed face simply becomes the underside of the desktop.

3️⃣ Essential Tools & Materials Needed

🔨 Tools (no table saw? No problem)

- Power drill/driver

- Circular saw or jigsaw + straight-edge guide

- Pocket-hole jig (Kreg R3 is $30)

- Level, stud finder, tape measure

- Socket set for the piston bolts

📦 Materials Checklist (Queen Vertical)

| Item | Purpose |

| ¾” plywood (4 sheets) | Cabinet carcass & face |

| 2×4 SPF lumber (8×8 ft) | Inner frame & legs |

| Murphy bed hardware kit (Amazon ~$120) | Pistons, hinges, fasteners |

| 2 Inches wood screws and need 1 ¼” pocket screws | All joints |

| Edge banding or iron-on veneer | Clean cabinet edges |

| Wood filler + paint/stain | Finish to match room |

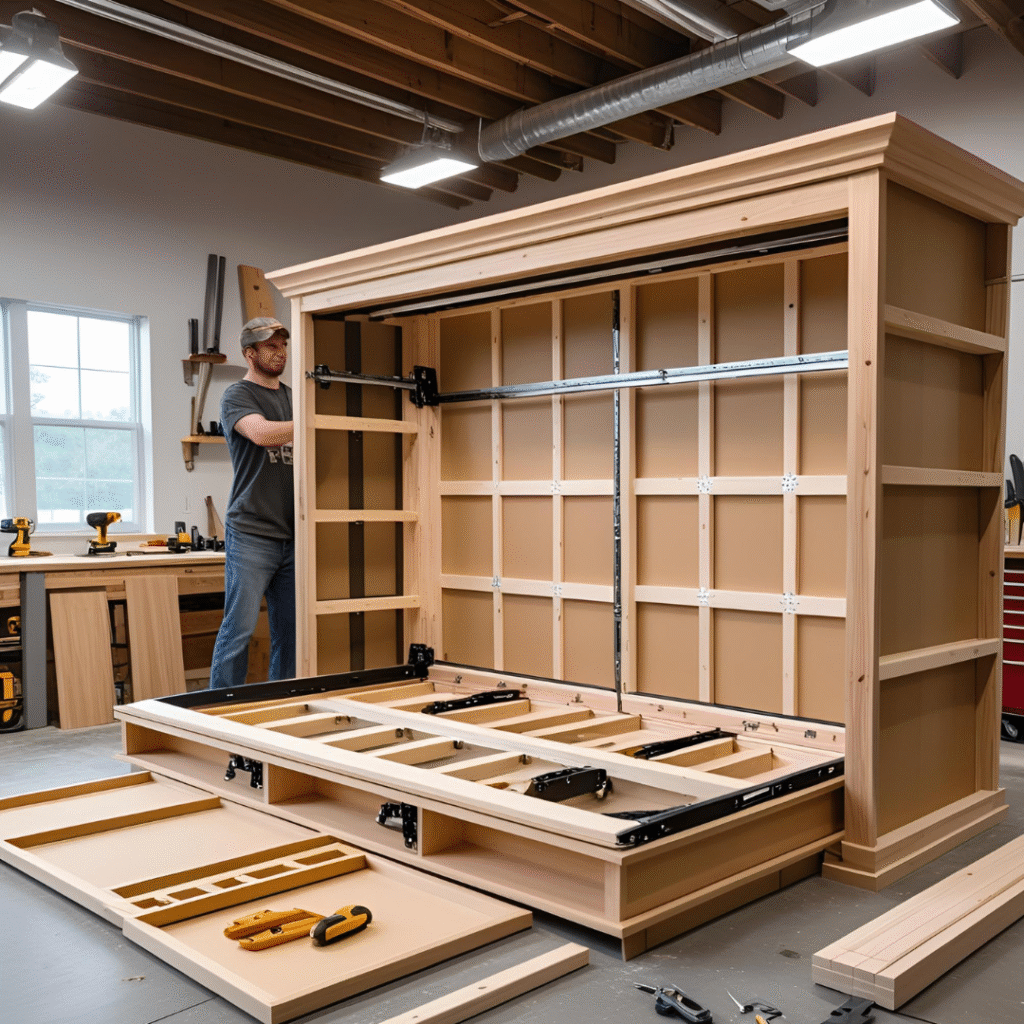

4️⃣ Step-by-Step DIY Murphy Bed Construction

📏 Step 1: Measure & Mark the Wall

- Find two studs 60″ apart (queen width).

- Mark 18″ off the floor for the bottom of the mattress box—gives 10″ clearance when folded.

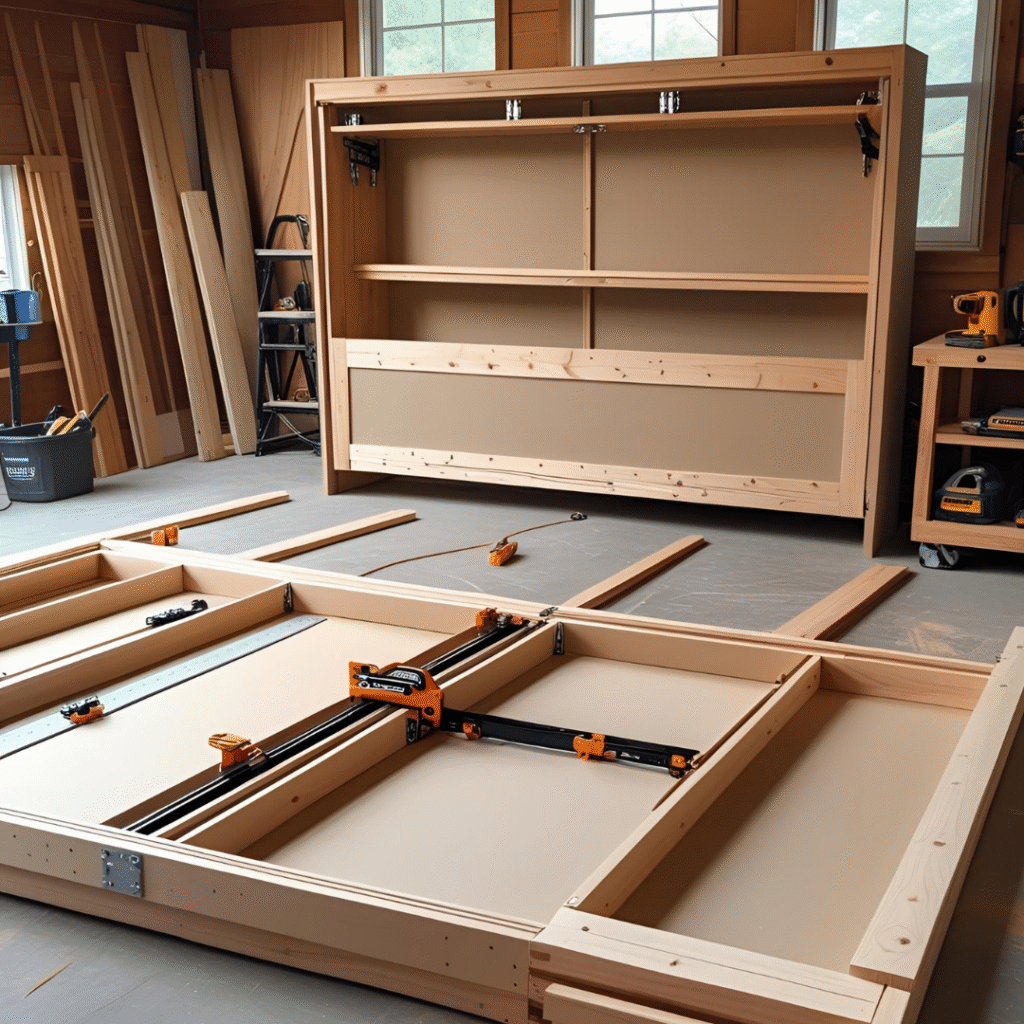

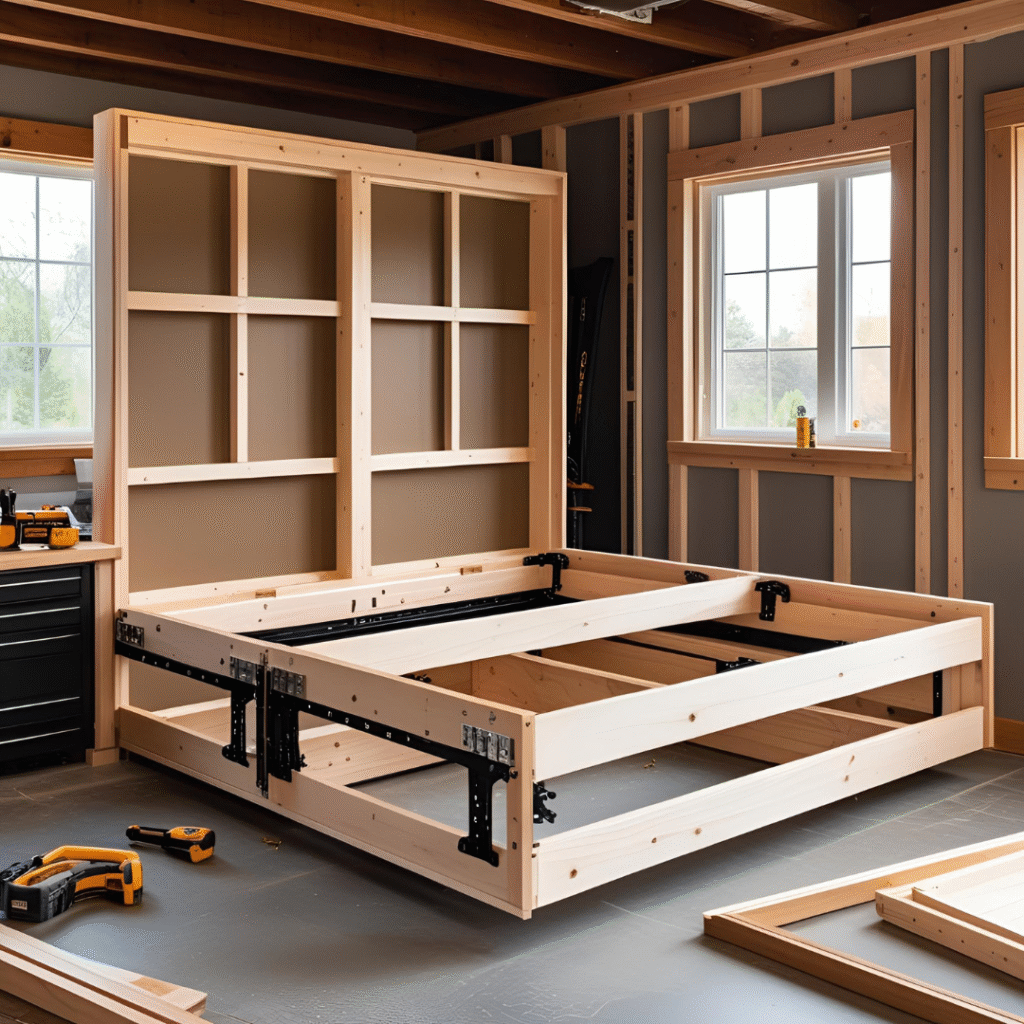

🔧 Step 2: Build the Inner Frame

- Cut four 2×4 rails: two at 80″ (length) and two at 60″ (width).

- Pocket-screw into a rectangle; add one center support at 40″ to prevent sag.

🔩 Step 3: Install the Hardware Kit

- Pistons: Bolt the lift arms to the inside of the side rails—arrow faces up or the bed won’t stay closed.

- Pivot brackets: Screw into wall studs first, then hook the frame. Use a helper—it’s awkward solo.

🪚 Step 4: Add the Mattress Box

- Face the underside, sides, and foot end with ¾” sheathing, creating a rigid box structure.

- Keep the top uncovered to allow airflow, preventing moisture buildup when the mattress is stowed.

🎨 Step 5: Build & Attach the Face Panel

- Frame a 65″×45″ rectangle out of 1×6 pine.

- Add decorative bead-board or painted MDF for a finished look.

- “Convertible Shelf-Desk: Mounted on hidden hinges, the bottom shelf swings down to reveal a built-in desk surface—tucking away cleanly when not in use.”

🛏️ Step 6: Safety & Finish

- Legs: Hinged 2×4 legs swing down effortlessly when the bed lowers, locking securely into place with ¼” dowel pins for rock-solid stability.

- Child lock: Simple barrel bolt on the side rail keeps toddlers from unfolding the bed.

5️⃣ Common Mistakes to Avoid

🚫 Skipping the Stud Finder

Drywall anchors alone will rip out. Always bolt into at least two wall studs.

🚫 Wrong Piston Orientation

If the piston arrow faces downward, the bed will launch open violently. Always verify orientation against the kit schematic before final assembly

🚫 Forgetting Clearance for Baseboards

Notch or remove ¾” from the baseboard behind the frame—skip this, and the bed will tilt forward, refusing to latch shut.

🚫 Using MDF for the Frame

MDF splits under shear forces. Stick to plywood or 2× lumber for the load-bearing parts.

🚫 Painting Before Final Assembly

Paint the face panel last; you’ll scuff edges while wresting the frame onto the wall.

🏁 Final Word

Transform any room with a sleek, disappearing bed—built in just 48 hours for under $400. With one hardware run and basic tools, you’ll craft a sturdy fold-up bed that tucks away effortlessly, freeing up your office, gym, or studio.

Pro Tips:

- Precision matters: Measure twice, bolt into studs.

- Let physics help: Gas pistons handle the weight.

- Breathe easy: Open-top design prevents moisture.

- Dual function: Drop-down panel becomes a desk when needed.

No more sacrificing your space—just smart, functional design.

The Genuine Tips + Maintenance, where actually you can find D.I.Y Murphy Bed Plans?

🛠️ Final Tips & Maintenance Cheat-Sheet

Keep your DIY Murphy bed folding like butter for the next decade.

🔧 Routine 5-Minute Check-Up (every 3 months)

- Regularly check and tighten piston arm and wall bracket bolts—constant motion can work them loose over time.

- Lubricate hinge pins it’s important lubricate them with few drops of 3-in-1 oil. Don’t forget to wipe excess to avoid carpet stains.

- Vacuum the cabinet floor to stop grit from gouging the mattress cover.

- Test safety latch—if it pops open too easily, bend the spring tab back 1 mm.

🧽 Mattress TLC

- Air-out cycle: After every guest, leave the bed down for 30 min with a ceiling fan on—prevents “closet” smell.

- Spot clean only: Act fast with a barely-wet soapy cloth, carefully avoiding contact with unfinished plywood edges where water penetration could cause swelling.

- Rotate mattress 180° every 6 months so the same edge doesn’t bear weight when vertical.

🎨 Refresh the Finish

- Touch-up paint pen matches cabinet color from any big-box store; keep one in the junk drawer for dings.

- Paste wax on the cabinet face once a year keeps fingerprints from sticking.

📍 Where to Find Rock-Solid DIY Murphy Bed Plans

| Source | What You Get | Best For | Price |

| Instructables DIY Modern Murphy Bed | 12-step photo guide + video + printable cut list | Visual learners | Free |

| D.I.Y Pete –Building a Murphy Bed | Hardware-kit walk-through + YouTube demo | First-time kit buyers | Free guide / kit Paid |

| Lori Beds | Strap-free, spring-free plans + $200 discount | Beginners who hate pistons | Plans $0 / kits Paid |

| Family Handyman – Bookcase Murphy Bed | Full magazine article + cut diagrams | Storage combo builds | Free w/ email |

| Create-A-Bed Video Series | 20-min YouTube build using cherry hardwood | Advanced woodworkers | Free |

| Woodsmith Plans (via Woodpeckers) | Premium shop drawings & exploded views | Pro-grade accuracy | Few bucks for downloading |

🎯 Quick Start Starter Pack

- Download the Lori Beds free plan (no pistons).

- Order a Create-A-Bed hardware kit on Amazon ($299) if you want gas-spring lift.

- Watch DIY Pete’s 20-min video once before you cut a single board.

Build once, fold forever.

How often should I tighten the bolts on my Murphy bed?

🔧 How Often Should I Tighten the Bolts on My Murphy Bed?

Keep it simple: every 3 months or any time the bed feels wobbly or sounds squeaky—whichever comes first.

Quick Schedule

- Quarterly (every 90 days)

Grab a socket wrench and give every piston bolt, hinge screw, and wall bracket a ¼-turn snug-up . - After heavy use (family visits, Airbnb turnovers)

Guests mean extra up-and-down cycles. Do a 60-second check once they leave. - If you hear a new rattle

Don’t wait—tighten on the spot. A bolt left untightened will gradually deform its mounting hole over time

30-Second Spot Check List

- 🔍 Piston arms (where the lift meets the side rails)

- 🔍 Wall lag bolts (top and bottom brackets into studs)

- 🔍 Leg pivot screws (if your bed has fold-down legs)

Use a hand-tight plus ⅛-turn rule: snug, but don’t over-torque and strip the threads. A drop of blue Loctite on wall bolts keeps them from backing out between seasons.

Bottom line: calendar reminder every season + an after-guest once-over keeps your Murphy bed rock-solid for years.

What if I don’t want to use pistons for my DIY Murphy bed?

🙅♂️ No Pistons? No Problem—Three Piston-Free Murphy Bed Options

If you’d rather skip the gas struts (or just hate the price tag), here are proven ways to get a smooth fold-up without them.

1️⃣ The Lori / YouLift “Human-Powered” Frame

- How it works

The system pairs a minimal-weight plywood platform with your choice of securement: locking pins for rapid disassembly or sliding bolts for permanent stability. You and a partner lift/lower by hand; gravity + counter-weighted legs do the rest. - Pros

• No hardware kit to buy (~$120 saved)

• Works with mattresses up to 12″ thick & 1,000 lbs total - Cons

• Requires two people for the first 6–8 lifts until muscle memory kicks in - Where to get plans

Free PDFs at loribeds.com or Instructables “DIY Modern Murphy Bed”

2️⃣ Torsion-Bar / Counter-Balance Hinges

- How it works

Replace pistons with a steel torsion bar hidden inside the side rails. The bar twists as the bed lowers and springs back to help lift. - Pros

• Whisper-quiet, no yearly re-pressurizing

• Rated for 15-year cycles - Cons

• Slightly bulkier side rails (adds ¾”) - Where to buy

Rockler Woodworking “Torsion-Assist Murphy Hardware” (~$189)

3️⃣ Old-School Spring Hinges (Budget Route)

- How it works

Heavy-duty screen-door springs or garage-door torsion springs bolt to the wall plate and frame. Adjust tension by moving the hook position. - Pros

• Parts cost < $30 at any hardware store - Cons

• Needs precise tension math—too loose = bed slams, too tight = won’t stay down - Pro tip

Use dual springs rated for at least 50 lbs each and always install safety cables inside the coils.

🛠️ Quick-Start Checklist for Piston-Free Builds

- Pick a weight limit: 1,000 lbs total (mattress + sleepers) max for Lori/YouLift style.

- You can Easily Download the free Lori vertical plan—it lists exact board cuts as well as bolt sizes.

- Grab two helper clamps when you dry-fit; the first lift is always the heaviest.

- Add rubber doorstops on the floor as a fail-safe catch if a spring ever slips.

Skip the pistons, save the cash, and still fold like a pro.

What’s the maximum weight capacity for the torsion-bar hinges?

⚙️ Maximum Weight Capacity for Torsion-Bar Hinges

(used in piston-free Murphy beds)

| Hardware Source | Rated Load (per pair) | Application Notes |

| Rockler Lid-Stay Torsion Hinge Set | 60–250 lb total door/lid (15–60 in-lb models) | Combine 2–4 hinges to match bed weight |

| Weber Knapp Counterbalance Hinges | Up to 200 lb panel | Industrial-grade, adjustable torque |

| Southco CB Series | 200–500 lb door | Feels like 5–10 lb when opening |

| Murphy-specific DIY kits (e.g., Create-A-Bed Torsion Kit) | 600–1,000 lb bed + mattress | Designed for queen/king beds |

🎯 Rule of Thumb

- Queen-size bed + mattress ≈ 80–120 lb

- Use two 250 lb-rated torsion hinges for a 2× safety factor.

- Always check the manufacturer’s torque chart (in-lb or N·m) and match center-of-gravity distance of your bed frame.

If your build exceeds 1,000 lb total, step up to heavy-duty counterbalance hinges or dual torsion bars.

How do I calculate the required torque for my bed?

(Bed Torque Calculation Formula)

⚡ How to Calculate the Required Torque for Your DIY Murphy Bed

You don’t need an engineering degree—just five minutes and a tape measure.

1️⃣ The Simple Formula

Torque = Weight × Distance

Where:

- Weight = total weight of bed frame + mattress + bedding in pounds (lbs)

- Distance = “Distance refers to the horizontal span (ft) from the rotational axis to the weight’s central point.”

2️⃣ Step-by-Step Example

| Step | What to Measure | Typical Queen Values |

| a. Weigh the bed | Frame + mattress + sheets | 160 lbs |

| b. Find the center of gravity | Measure from pivot to mid-mattress | 3.5 ft |

| c. Plug in | Torque = 160 × 3.5 | 560 lb-ft |

3️⃣ Match Hardware to the Number

- Torsion bars are sold in 100–1,000 lb-ft increments in pairs.

- Rule of thumb: choose a pair rated 2–2.5× your calculated torque for smooth, one-hand operation.

Example: 560 lb-ft → pick 1,100 lb-ft torsion pair.

4️⃣ Quick Sanity Check

- If the bed drops like a rock → hardware is under-rated.

- If it takes two people to lift → hardware is over-rated or pre-load is too high.

That’s it—measure once, buy once, fold forever.

How do I measure the distance accurately?

📏 Measuring “Distance” for Torque Calculation – A 3-Minute Pro Method

You only need a tape measure and a helper (or a couple of clamps and a level).

1️⃣ Find the Pivot Axis

- Establish reference marks at the precise midpoint of each hinge pin’s mounting location.

- That line is your zero-point.

2️⃣ Locate the Center of Gravity (CG)

- With mattress on the frame, slide a long 2×4 under the bed until it balances on the edge of the frame.

- This marked balance position establishes the exact lengthwise center of gravity.

3️⃣ Measure Horizontal Distance

- Measure straight out from the pivot axis to the CG mark while the bed is horizontal (fully open).

- Keep the tape perpendicular to the wall—a cheap level across the tape prevents tilt errors.

4️⃣ Double-Check

- Repeat on the other side; the two numbers should be within ½”.

- Average them to cancel any slight frame twist.

Pro tip: If the bed feels nose-heavy after you install the torsion bars, re-measure with bedding—a thick comforter can move the CG another 2–3 inches.